- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 0

- Place of Origin: Shandong, China

- Brand Name: SANLONG

- Model Number: SLSY1012

- Weight: 340.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :

Overview

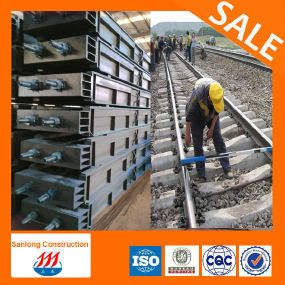

Concrete sleeper is also called concrete pillow, tie . Made of concrete, reinforcement steel bar , whose appearance is strong and have a long service life.

Concrete sleepers in accordance with the structure can be divided into U-shaped ring and pressure plate bolts.

U-shaped concrete sleepers ring easy to install, simply put the rail between two U-rings, rubber pad underneath it, and then using a sledgehammer spending a U-shaped loop to suppress rail. Concrete sleepers bolt plate is to use T-bolt holes from piercing reserved sleeper following fixed platen press and hold the rail above, a sleeper requires four sets of bolts, 4 plate, two rubber pads, this sleeper easy maintenance , can be reused.

Advantages

Concrete sleepers need a molding steam stripping, appearance is smooth, hard, and contains many root rebar.

Cement pillow wood source widely, the same specifications, uniform elasticity, good insulation, high stability, is not affected by external conditions such as temperature of the weather, don't decay long service life.

The prestressed concrete sleeper in addition to a large number of high quality steel products, saving and long service life, good stability, orbit can satisfy the requirement of high speed, large capacity, etc.

Specifications

1, normal sleepers: Width 220mm; thickness 160mm; length 2500mm;

2,turnout sleepers (Normal): Width 220mm; thickness 160mm; length 2600 ~ 4850mm, with 150mm carry a total of 16 lengths;

3,turnout sleepers (Standard): Width 240mm; thickness 160mm; length 2600 ~ 4800mm, with 200mm carry a total of 12 lengths;

4,bridge sleepers: Width 220mm; thickness 240,260,280,300 mm; length 3000mm;

Features

1. Advanced Welding technology, which enhances smooth finish of the mould wall and surface and eliminates uneven traces of rivet holes.The surface of concrete poles will be improved obviously.

2. The pole mold cylinder is changed to U-type longitudinal stiffeners. This structure can greatly increase the stiffness and flexural strength of the steel mould.

3. Install the slot with rubber sealing strip, in order to prevent leakage to ensure quality.

Concrete Pole Production Process

1. Raw Materials Preparation

prepared raw materials required for the producing of cement poles.Production raw materials include: steel, sand, gravel, and cement.We should choose high quality steel bar, cement that is strong resistance to pressure,choose fast solidification and low density cement.Sand should be filtered to prevent other magazines doping.

2 Steel Cage Forming Process

Use straightening & cutting machine to straighten and cut steel bar in accordance with the provisions. After finishing straightening steel bar,send them to the next program.Please note that the straightening of steel should be cut off according to the length of cement pole. Length should be accurate. It is crucial for the steel bar is equivalent to concrete pole skeleton .

3. Tension Steel Cage

4. Concrete Distribution Process

Place the steel cages in the open mold .After pouring with cement with concrete distribution machine , cover the cover mould.After confirmation on both sides of the gap smaller or closed, finally plug two sides with pouting lips fortress to prevent the outflow of cement.

5. Centrifugal Spinning

After closing the mold and hoist with crane onto the spinning machines . Then start the spinning process . It will take three different speed regulating steps , totall 15 minutes . At this step , speed variable control cabinet and motor is suggested .

6. Steam Curing

It's one of most imporatant process for the concrete pole production . With the steam supplying into the steam curing pool by the steam boiler , the concrete poles in the mold will be treated with four hours at least in the pool . At different period , concrete poles will need different temperature . And at about 86 degree , the temperatue should keep steady .

7. Inspection of Finished Concrete Poles

8. Storage of Qualified Concrete Poles

We supply complete concrete pole machines and be responsible for installation and commissioning and also workers production training service .

Any questions . pls don't hesitate to contact me !

- Size: 0

- Place of Origin: Shandong, China

- Brand Name: SANLONG

- Model Number: SLSY1012

- Weight: 340.000 kg

- :

- :

- :

- :

- :

- :

- :

- :

- :